What is an electric generator? Complete guide to operation and types

Today, electricity is an indispensable resource for our daily activities, andelectric generators have become essential devices for ensuring a constant supply of energy . From hospitals requiring immediate backup to remote construction sites, these devices transform various forms of energy into electricity, powering homes, businesses, and industries around the world.

But what is anelectric generator ? It's not simply a backup machine; it's a technology that has revolutionized energy production and distribution, allowing electricity to reach the most isolated locations and ensuring energy security in critical situations. In this comprehensive guide, we'll explore in depth what an electric generator is, how it works according to fundamental physical principles, the existing types, its main components, and the multiple applications that make this technology a pillar of modern energy infrastructure.

Comcast Group: Reliable Generators for Every Sector

Comcast Group is a leading provider of power generation solutions, offering equipment designed to meet the demands of diverse industrial and commercial sectors. Our expertise spans a wide range of applications, ensuring reliable and continuous power in the most demanding environments.

Sectors we cover

We provide energy solutions for multiple sectors, including:

- Energy for Telecommunications

- Hotels

- Hospitals

- Industry

- Construction and Metals

- Audio and Events

- Agricultural Sector

- Food and Beverages

- Metallurgy and Extraction

- Government and Public Services

- Chemicals

- Health and Pharmaceutical

- Technology and Telecommunications

- And many more!

Power options for any need

At Comcast Group, we offergenerators with capacities ranging from 9 kW to 2,000 kW , ideal for covering any power requirement. Our generators start instantly and maintain power without fail, ensuring continuous and reliable operations.

Examples of our options include:

- 10kW Generator : Compact and efficient for small applications or home backup.

- 20 kW generator : ideal for businesses and small industries that require greater power.

- 30kW Generator : Designed for medium-sized industrial operations and events that demand stable power.

These units feature a quiet, low-power design, ensuring reliable, trouble-free operation even in the most demanding environments.

Definition and basic concepts

An electric generator is a machine designed to convert mechanical energy into electrical energy through the phenomenon of electromagnetic induction. This rotating machine serves the vital function of providing a reliable source of electricity in multiple sectors, from residential use to large-scale industrial facilities and critical services.

The operation of an electric generator is based on maintaining a potential difference or voltage between its terminals through the interaction of a magnetic field and moving electrical conductors. This principle, based on Faraday's law, has been the technological basis for mass electrification since the 19th century and for the development of modern electrical distribution systems.

Generators are primarily composed of two essential parts: the rotor and the stator. The rotor is the moving part that rotates within the stationary stator. In this assembly, one part acts as an inductor, generating the magnetic field, while the other is the armature, where the magnetic flux is transformed into electricity. Depending on the type of current they produce, generators are divided into alternators, which generate alternating current, and dynamos, which generate direct current.

The mechanical energy that drives these generators can come from a variety of sources, such as internal combustion engines running on diesel or natural gas, hydraulic turbines harnessing the power of water, wind turbines driven by wind, steam turbines in thermal power plants, or even nuclear energy.

Operating principle: Faraday's Law

The fundamental principle that explains how an electric generator works is Faraday's law of electromagnetic induction. This law states that the emf generated in a closed circuit is equal to the negative value of the rate of change of the magnetic flux passing through it.

In simple terms, when an electrical conductor, such as a copper coil, moves within a changing magnetic field, an electric current is generated proportional to the rate of that change. Thanks to this phenomenon, it is possible to directly convert mechanical motion into electrical energy.

A historical example that illustrates this principle is the Faraday disc, the first electromagnetic generator in history. It consisted of a copper disc that rotated between the poles of a permanent magnet. As it rotated, the disc created a constant variation in the magnetic flux, inducing an electric current captured at the disc's edges.

How an electric generator works in practice

In practice, when a conducting coil rotates within a magnetic field, it experiences continuous changes in the magnetic flux passing through it. These changes induce an alternating electromotive force that varies depending on the coil's position relative to the magnetic field lines. The production of electricity in a generator depends on the magnetic flux that cuts through the conductor, making this phenomenon essential to its operation.

This process can be described in four key steps:

- Relative motion: The rotor rotates within the magnetic field generated by the stator.

- Variation of the magnetic flux: The movement causes constant changes in the magnetic flux that passes through the coil.

- Current induction: The variation of the magnetic flux induces electric currents in the conductors.

- Energy Harvesting: Induced currents are captured and conducted to the output circuit for use.

This principle underlies all modern generators, from small portable units to large machines in power plants. The differences lie in scale, materials, and control systems, but the physical foundation remains constant.

Types of electric generators

Electric generators are classified primarily according to the type of current they produce, which determines their specific characteristics and applications. There are two broad categories: alternating current generators (alternators) and direct current generators (dynamos).

Alternating current generators (alternators)

Alternators are the predominant technology for large-scale electricity generation. These generators convert mechanical energy into electrical energy, producing alternating current, where the direction of the current changes periodically in a sinusoidal pattern.

In a typical alternator, the rotor acts as an inductor and contains coils powered by direct current to create the necessary magnetic field. The stator acts as an armature and houses the windings where electricity is generated. The rotor's rotational speed, along with the number of magnetic poles, determines the frequency of the current produced.

The main features of alternators include:

- Production of electricity with standard frequencies (50 Hz in Europe, 60 Hz in America).

- Compatibility with various propulsion systems, such as hydraulic turbines, steam turbines, or internal combustion engines.

- Need for excitation systems to power the rotor coils.

- Speed and voltage regulation to maintain grid stability.

- Greater efficiency in energy transmission over long distances.

Thanks to these advantages, alternators dominate centralized power generation, since alternating current can be easily transformed by transformers to adapt the voltage to transmission and consumption needs.

Direct current generators (dynamos)

Dynamos were the first industrial machines for generating electricity in the 19th century. They produce direct current through a mechanical switching system that converts the alternating current initially induced in the rotating coils into a stable direct current.

The distinctive element of a dynamo is its commutator, a set of insulated conductive segments that, together with carbon brushes, allow for the mechanical rectification of the current, always maintaining the flow in a single direction.

The main characteristics of dynamos are:

- Production of direct current without the need for electronic rectifiers.

- Use of mechanical switches that require regular maintenance.

- Power limitations due to brush wear.

- Excellent speed control when operating as motors.

Although they have been largely replaced by alternators in centralized generation applications, dynamos remain useful in specific applications requiring precise speed control.

Main components

An electric generator is composed of several key components that work together to efficiently convert mechanical energy into electrical energy. Each component performs a specific function that influences the generator's performance and durability.

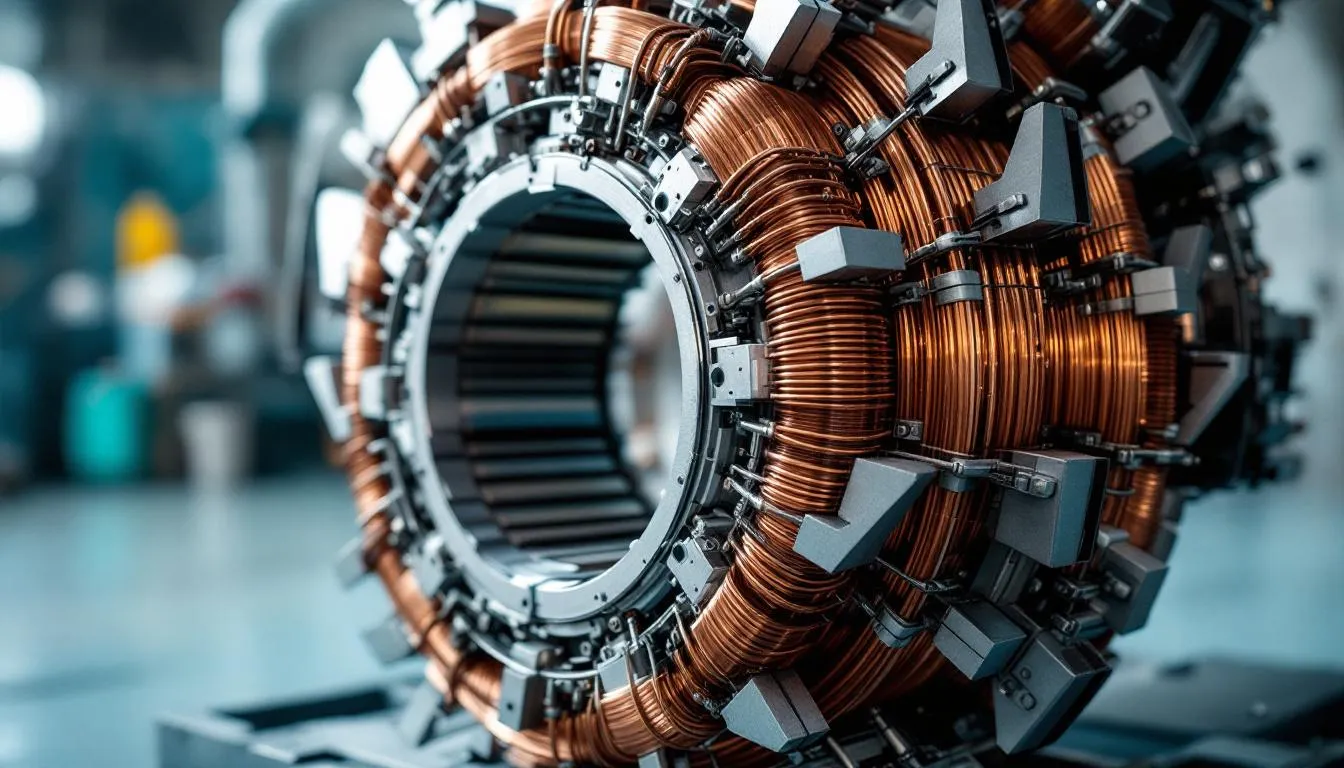

Stator

The stator is the fixed part of the generator and one of its most important components. It is made of stacked and insulated silicon steel sheets to reduce eddy current losses. The stator contains the copper windings where the electric current is induced.

Its main functions include:

- Provide mechanical support to the assembly.

- To house the windings where electricity is generated.

- Create an efficient magnetic path for the flux.

- Dissipate heat generated during operation.

Rotor

The rotor is the moving part that rotates within the stator and generates the magnetic field necessary for electromagnetic induction. It may contain copper coils powered by excitation current or permanent magnets, depending on the design.

The rotor must be perfectly balanced to avoid vibrations that could damage the generator. Its technical features include variable operating speeds, precision bearings, and ventilation systems to dissipate heat.

Air gap

The air gap is the air space separating the rotor from the stator. Although small (between 1 and 3 millimeters), it is essential for the proper functioning of the generator, as it allows the rotor to spin freely and affects magnetic efficiency.

An air gap that is too large reduces efficiency, while one that is too small can cause friction and mechanical damage. Therefore, maintenance and monitoring are essential.

Additional generator systems

To operate safely and reliably, electric generators incorporate auxiliary systems that optimize their performance and protection.

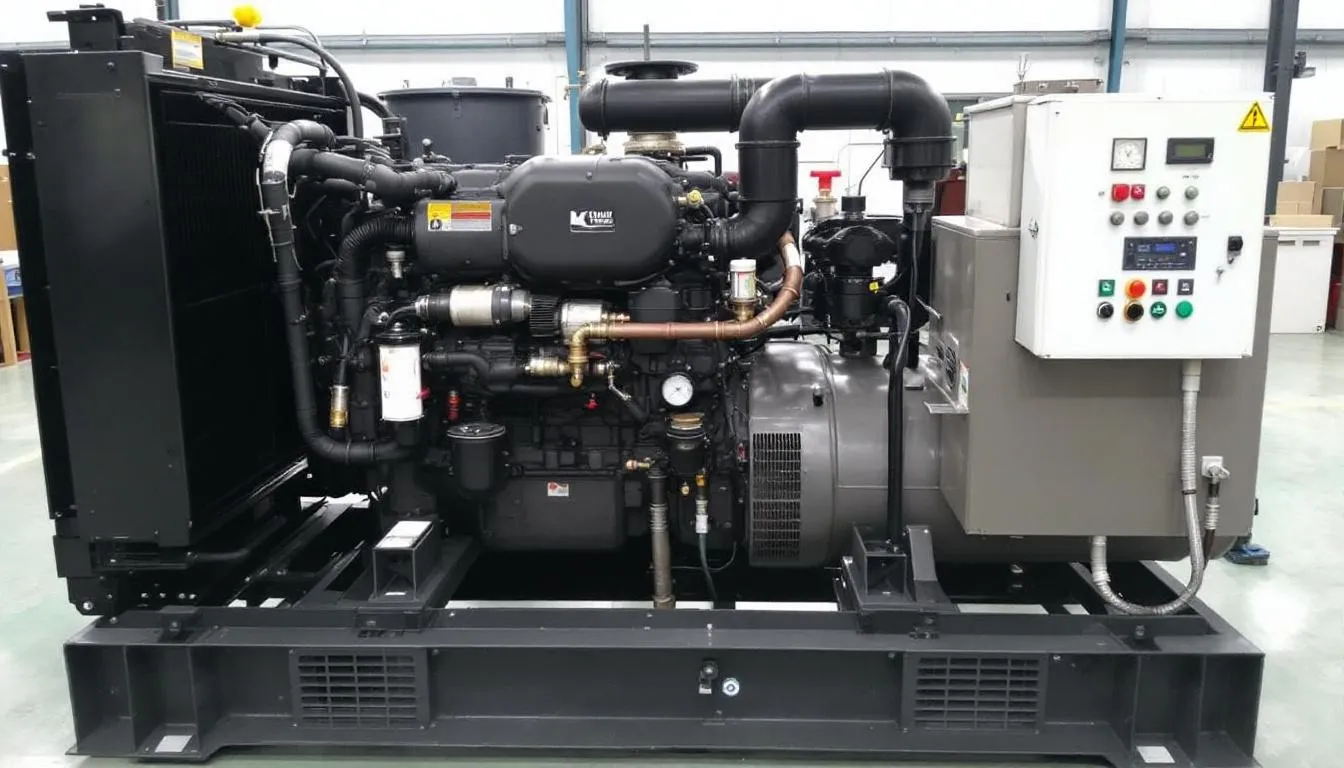

Prime mover and fuel system

The prime mover, usually an internal combustion engine, provides the mechanical energy that drives the generator. Diesel engines are common due to their efficiency and durability. The fuel system includes tanks, pumps, filters, and injection systems that ensure a constant supply.

Control and regulation systems

Modern generators feature speed controllers that maintain a constant frequency, voltage regulators that adjust the output voltage, and protection systems against overloads, short circuits, and overheating.

Auxiliary systems

They include starting batteries, cooling and lubrication systems, exhaust systems, and, in critical applications, automatic starting, transfer switches, and remote monitoring.

These systems allow the generator to operate autonomously and safely for extended periods, especially in applications where continuity of supply is vital.

Applications and practical uses

Power generators are versatile and are used in numerous sectors and situations.

Emergency power supply

In hospitals, data centers, and telecommunications stations, generators guarantee immediate power in the event of grid failures. They must be reliable, start up quickly, and operate for days without replenishment.

Generation in remote areas

In isolated rural areas, mines, research stations, and island communities, generators provide electricity where the grid doesn't reach, facilitating development and improving quality of life.

Industrial and commercial applications

Some industries use generators as a primary source to control costs, improve energy quality, and achieve independence from the public grid. Furthermore, generators are essential for industrial automation, allowing operation without connection to the power grid and ensuring the continuity of production processes.

Construction sector

Portable generators power tools and equipment in locations without electrical infrastructure and must be robust, efficient, and easy to transport.

Recreational and home applications

In homes, outdoor events, and recreational activities, generators provide backup power during power outages and make it easier to use electrical devices in locations without grid access.

|

Application Type |

Typical Power |

Common Fuel |

Time of Use |

|---|---|---|---|

|

Portable home |

1-5 kW |

Gasoline |

8-12 hours |

|

Residential support |

10-20 kW |

Natural gas/Diesel |

Days/weeks |

|

Small commercial |

20-100 kW |

Diesel |

Days |

|

Industrial |

100-1000+ kW |

Diesel/Natural Gas |

Continuous |

|

Power plant |

100-1500 MW |

Multiple fuels |

Continuous |

Advantages of alternators over dynamos

The alternator is the predominant electrical machine in power generation due to several technical and economic advantages over dynamos.

Superior transmission efficiency

Alternating current generated by alternators can be easily transformed to increase or decrease voltage, enabling high-voltage transmission with lower losses and operating costs.

Less maintenance and greater reliability

Without mechanical commutators or brushes, alternators require less maintenance, have a longer lifespan, better thermal performance, and operate more quietly.

Operational advantages

They offer stability under variable loads, grid synchronization capabilities, precise frequency control, and scalability from portable units to power plants.

Predominance in the current market

These advantages have led to 99% of the world's centralized generation using alternators, relegating dynamos to specific applications where their speed control is valuable.

Conclusion

Electric generators are fundamental technologies that have transformed the way we produce and use electrical energy. From the basic principles of Faraday's law to today's sophisticated machines, these devices convert mechanical energy into electricity, ensuring reliable power supplies in a variety of applications.

The predominance of alternators reflects the constant quest for efficiency, reliability, and economy in energy systems. With advances in materials, intelligent controls, and integration with renewable energy, electric generators will continue to be key components of a sustainable energy future.

Whether providing emergency power in hospitals, powering buildings at remote sites, or generating electricity on a massive scale, these devices demonstrate how the application of fundamental physical principles can light and power the modern world.